The SRL team is more than 300 people strong with 5 Ph.Ds., 70 M.Scs., 80 B.Scs., 15 MBAs 50 field staff, 38 depot employees, 3 research associates and other skilled employees at the head office and a strong workforce at Factory locations.

As opposed to what SRL was during its inception years in the 1970s, today SRL has 4 state-of-art production facilities in Mumbai & Chennai producing 20000 SKUs of various grades, segments and packing sizes and 5 Distribution warehouses.

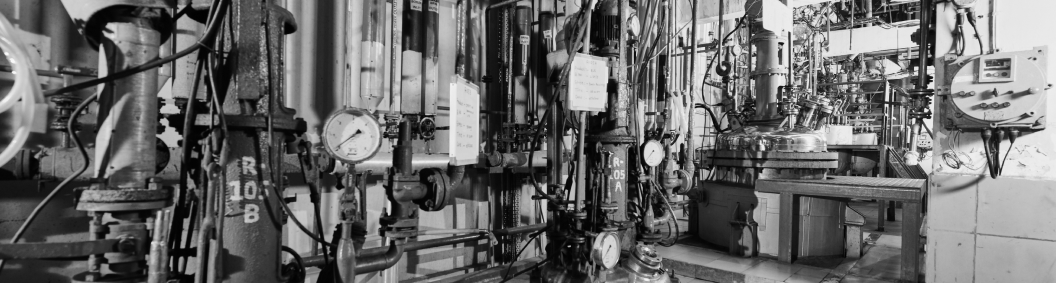

For our chemical processes, we process and synthesize all products in Glass-lined, SS or PTFE vessels to keep the products free from ionic, metallic or other contaminants depending on the products which are being processed. The plants handling these complex chemical and biochemical products are FDA approved and operate using cGMP guidelines.

We have pioneered the production of several reagents like Agaroses, Methylenebisacrylamide, Sodium Lauryl Sulphates, Gel Filtration Media, Electrophoresis Reagents, Atomic Absorption Standard Solutions (AAS), Sodium Biphenyl and many other speciality Reagents and Biochemicals used in research and in industry.

At our production plants, personnel safety and avoidance of hazards are our primary concern. The plant undergoes semi-annual shut-downs and maintenance which make sure that all Unit operations and Utilities are operating at optimum efficiency.

For our microbiological culture media manufacturing, we require environmentally controlled conditions for the production process.. The entire production facility is maintained as Strictly Restricted and Class 8, CE certified and the production is done in SS vessels.

All our media are manufactured using state-of-the-art technology thereby preventing any possible contamination of the product and maintaining the nutritional and restrictive properties of the final product. It is perhaps due to this dedication and obsessiveness to quality, that our products are the first-preference media to more than half the research done within the country and in the Asian continent.

D-88/2, TTC Industrial Area,

Turbhe, Navi Mumbai, Maharashtra - 400705, India.

Plot No. H-4, Taloja Indl. Area, MIDC,

Padghe, Panvel, Dist Raigad, Maharashtra - 410208, India.

Kumara No. 21, Ground Floor, Thomas Nagar,

Little Mount, Chennai, Tamil Nadu - 600015, India.

1st Floor, D-88/2, TTC Industrial Area,

Turbhe, Navi Mumbai, Maharashtra - 400705, India.